1. Structure

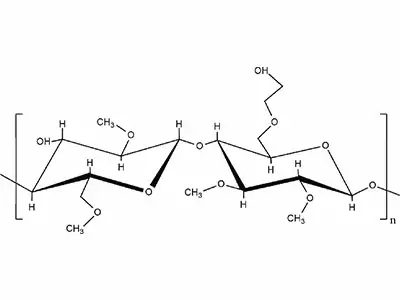

1.1 HPMC

HPMC (hydroxypropyl methyl cellulose)(Fig. 1), the raw material produced can be refined cotton or wood pulp, which is part of the methyl group and part of the polyhydroxypropyl ether of cellulose. It is obtained by etherification with propylene oxide and methyl chloride. The structure such as HPMC has thermal gel properties, and its solution has no ionic charge and does not interact with metal salts or ionic compounds. It has strong antifungal properties, as well as good dispersing, emulsifying, thickening, cohesive, water-retaining, and gum-retaining properties.

1.2 HEMC

HEMC (Hydroxyethyl methyl cellulose)(Fig. 2) is slightly different from HPMC in production and preparation. After cellulose is alkalized, ethylene oxide is used to replace propylene oxide and the hydroxyl group on the glucose ring group is replaced. Compared with HPMC, the chemical structure of HEMC has more hydrophilic groups, so it is more stable at high temperatures and has good thermal stability. Compared with the common HPMC, it has a relatively high gel temperature, which is more advantageous in a high-temperature use environment.

2. Chemical properties

2.1 Gel temperature

Gel temperature is an important indicator of cellulose ether. The cellulose ether aqueous solution has the characteristics of thermal gelation. The gel temperature test method refers to preparing the cellulose ether sample into a cellulose ether solution with a concentration of 0.2%, and slowly heating it in a water bath until the solution appears white turbid or even white gel, and completely loses its viscosity. At this time, the temperature of the solution is the gel temperature. The overall gel temperature of HEMC is slightly higher than that of HPMC.

In general, the gel temperature of Michem HPMC is between 60°C and 75°C, and that of Michem HEMC is between 75°C and 90°C. (Fig. 3)

3. Applications in the construction industry

Michem HPMC and Michem HEMC have similar roles in building materials. It can be used as a dispersing agent, water retention agent, thickener and binder, etc. It is mainly used in the molding of cement mortar and gypsum products. In practical applications, in the very hot construction environment in summer, HEMC with the same viscosity and dosage has a greater advantage in water retention in the wet-mixed mortar than HPMC. Especially in tropical countries, the mortar is sometimes constructed at high temperatures, and the cellulose ether with too low a gel temperature will lose the inherent thickening and water retention properties of the cellulose ether at high temperatures, thereby accelerating the solidification of cement and mortar.