Cellulose ether is an important chemical compound used in the construction industry as a binder, thickener, and stabilizer. One of the most widely used types of cellulose ether in the construction industry is hydroxyethyl methyl cellulose (HEMC). This article will discuss HEMC, its properties, and its applications in the construction industry, particularly in drymix mortar.

What is HEMC?

HEMC is a water-soluble polymer that is derived from cellulose. It is made by reacting cellulose with an alkali to form alkali cellulose, which is then reacted with ethylene oxide and methyl chloride to produce HEMC. HEMC is available in various grades, with different levels of viscosity and other properties, to suit different applications.

Properties of HEMC

HEMC is added to mortar to improve its properties and enhance its performance.

1. Water Retention

HEMC is an excellent water retention agent, it can hold water in the mortar for longer periods of time. This property is essential in mortar, as it ensures that the mortar remains workable for a longer period, and it reduces the need for additional water to be added to the mixture.

2. Workability

HEMC improves the workability of the mortar by making it easier to spread and work with. as it ensures that the mortar can be applied evenly and smoothly, reducing the risk of voids or weak spots in the wall.

3. Adhesion

HEMC improves the adhesion of the mortar to the bricks or stones in the wall. as it ensures that the mortar bonds well with the wall and reduces the risk of cracking or crumbling over time.

4. Durability

HEMC improves the durability of the mortar by increasing its resistance to water and weathering. as it ensures that the mortar remains strong and stable over time, even in harsh conditions.

Applications of HEMC

1. Tile Adhesive

HEMC is commonly used in tile adhesive to improve its bonding strength and durability. It works by acting as a water retention agent, ensuring that the adhesive remains workable for a longer period of time, and by enhancing the adhesion between the tiles and the substrate. HEMC also helps to improve the open time of the adhesive, which is the amount of time that the adhesive remains sticky after it has been applied to the substrate.

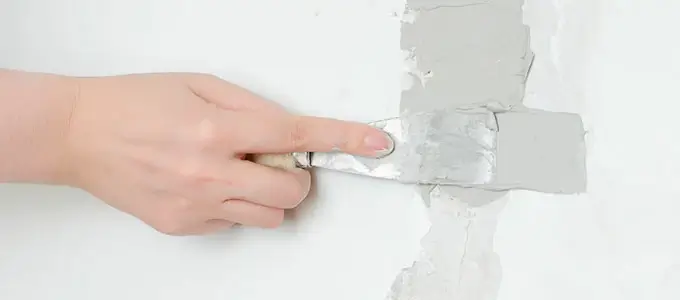

2. Wall Putty

HEMC is often used in wall putty to improve its workability and smoothness. It works by acting as a thickener and stabilizer, ensuring that the putty can be applied easily and evenly to the wall surface. HEMC also helps to improve the water retention of the putty, which reduces the need for additional water to be added to the mixture.

3. Plastering

HEMC is commonly used in plastering to improve the adhesion and workability of the plaster. It works by acting as a water retention agent, ensuring that the plaster remains workable for a longer period of time, and by enhancing the adhesion between the plaster and the substrate. HEMC also helps to improve the workability of the plaster, making it easier to apply and spread evenly over the surface.

Conclusion

HEMC is an important material in the construction industry, particularly in mortar. Its properties make it an excellent thickener, stabilizer, binder, and water retention agent, which improves the performance of mortar and enhances its durability. By using HEMC in their mortar, manufacturers can provide their customers with high-quality products that meet the demanding requirements of the construction industry.

Michem HEMC is a high-quality cellulose ether that is specifically designed for use in drymix mortars, If you’re looking for a high-quality HEMC product that can help you improve the performance of your construction materials, Contact us today to learn more.